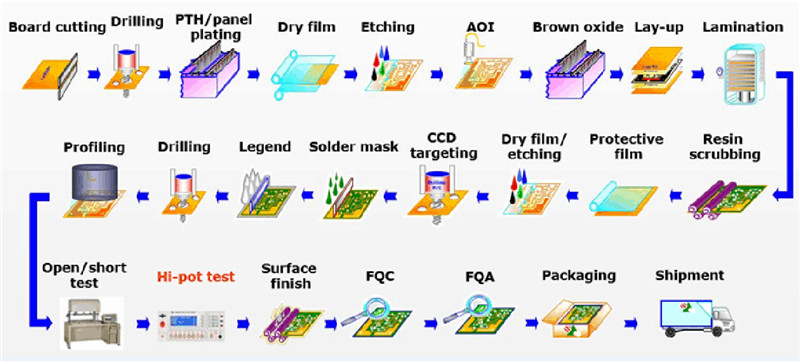

CB Manufacturing Process a very difficult and complex. Here we will learn and understand the process with the help of Flowchart.

The question can and probably should be asked: “Is it important to understand the PCB manufacturing process?” After all, PCB manufacturing is not a design activity, it is an outsourced activity that is performed by a contract manufacturer (CM). Although, it is true that fabrication is not a design task, it is done in strict adherence to the specifications that you provide to your CM.

In most cases, your CM is not privy to your design intent or performance objectives. Therefore, they would not be aware of whether you are making good choices for materials, layout, via locations and types, trace parameters or other board factors that set during fabrication and may impact your PCB’s manufacturability, production yield rate or performance after deployment, as listed below:

Manufacturability: The manufacturability of your boards depend on a number of design choices. These include ensuring that adequate clearances exist between surface elements and the board edge and the material selected has a sufficiently high coefficient of thermal expansion (CTE) to withstand PCBA, especially for no-lead soldering. Either of these could result in the inability of your board being built without redesign. Furthermore, if you decide to panelize your designs then that too will require forethought.

Yield rate: Your board can be successfully fabricated, while fabrication issues exist. For example, specifying parameters that stretch the tolerance boundaries of your CM’s equipment can result in higher than acceptable numbers of boards that are unusable.

Reliability: Depending upon your board’s intended usage it is classified according to IPC-6011. For rigid PCBs, there are three classification levels that set specific parameters that your board’s construction must meet to achieve a specified level of performance reliability. Having your board built to meet a lower classification than your application requires will likely result in inconsistent operation or premature board failure.

Post time: Feb-14-2023