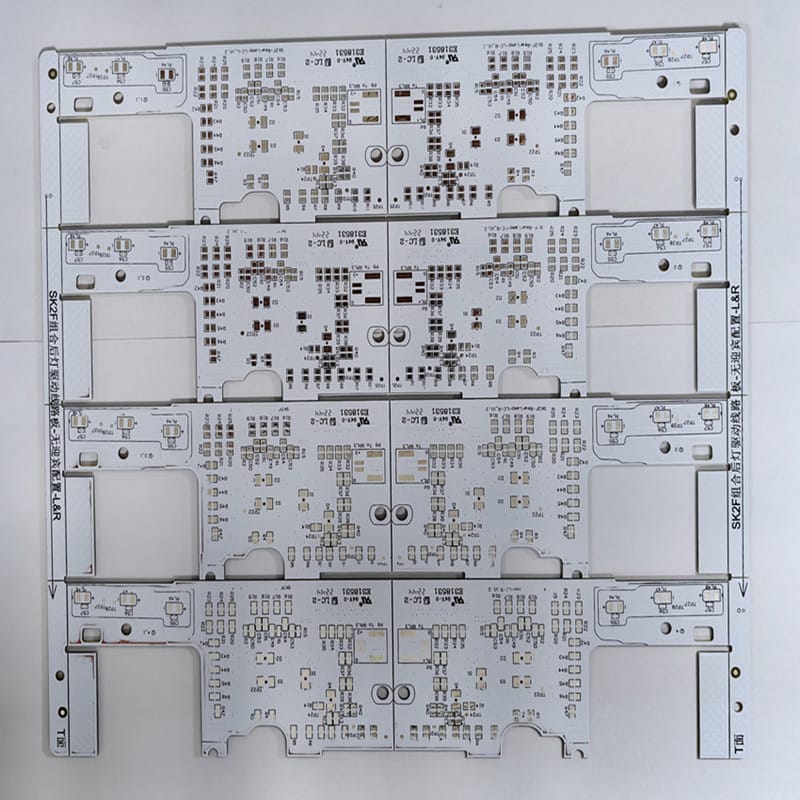

Fast turn PCB circuit board for LED light New energy vehicles

Product Specification:

| Base Material: | FR4 TG140 |

| PCB Thickness: | 1.6+/-10%mm |

| Layer Count: | 2L |

| Copper Thickness: | 1/1 oz |

| Surface treatment: | HASL-LF |

| Solder mask: | White |

| Silkscreen: | Black |

| Special process : | Standard |

Application

LED light refers to a lighting device that uses light-emitting diodes (LEDs) as a light source to emit light. Compared with traditional incandescent bulbs, LED lights have the advantages of higher energy efficiency, longer working life, smaller size, lighter structure, richer colors, etc., and do not generate too much heat and are more environmentally friendly. Therefore, there is a high demand for LED lights in the modern lighting market.

LED lights are used in a wide variety of fields, including:

1.Home and building lighting

2.Automotive lighting

3.Torch and Torch

4.Signage

5.Traffic signals and street lighting

6.Medical equipment

7.Electronic devices and gadgets

8.Horticulture and plant growth

9.Aquarium and terrarium lighting

10.Entertainment and stage lighting.

LED lights and printed circuit boards have a close relationship. Normally, LED lights need to go through the manufacturing process of printed circuit boards to complete the circuit construction. A printed circuit board is a substrate that connects electronic devices to each other, and it can realize the functions of electronic devices through circuit connection points. In the manufacturing process of LED lights, LED chips and supporting electronic devices need to be assembled on the printed circuit board, and the circuit construction is completed through the circuit connection points, so as to realize the normal operation of the LED lights. Therefore, printed circuit boards are an integral part of the LED lamp manufacturing process.

The characteristics of the LED PCB are as follows:

1.High reliability: Compared with the traditional light set, the light board made of printed circuit board is more closely connected to the physical circuit, and the reliability and stability of the circuit are higher.

2.Space-saving: The printed circuit board lamp board has advanced manufacturing technology, which can compress the circuit in a very small space, so the size is smaller, and more lamps can be embedded in a small space.

3.Easy to manufacture: The manufacturing process of the printed circuit board light board is simple, and the circuit prototype can be made with the help of a computer, which shortens the circuit manufacturing time and improves production efficiency.

4.Good repeatability: Compared with manual production, the production process of printed circuit board light boards has good stability, can realize mass production, and ensure high consistency of circuits.

5.High strength: The printed circuit board light board uses high-strength materials, and the circuit produced is not easily affected by mechanical shock and vibration, the circuit is not easy to be damaged, and the service life is longer.

FAQs

LED PCBs are specific types of printed circuit board, designed for use in a wide array of lighting modules and applications.

A number of light emitting diodes (LEDs) are mounted to a PCB forming a completed circuit, allowing full control of their behaviour through various types of chips or switches.

A white PCB provides a more uniform effect, coloring with the LED where a black PCB provides a clearer defined point of light, not absorbing the same color of the LED so making all the LEDs more singular.

Aluminum and FR4 material are the most common type of LED PCB.

LED is a highly energy-efficient lighting technology.Residential LEDs -- especially ENERGY STAR rated products -- use at least 75% less energy, and last up to 25 times longer, than incandescent lighting.