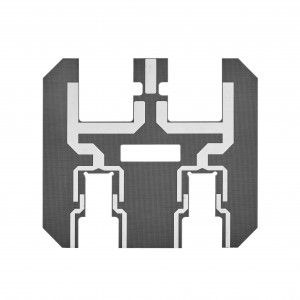

Custom 2-layer PTFE PCB

Product Specification:

| Base Material: | FR4 TG170 |

| PCB Thickness: | 1.8+/-10%mm |

| Layer Count: | 8L |

| Copper Thickness: | 1/1/1/1/1/1/1/1 oz |

| Surface Treatment: | ENIG 2U” |

| Solder Mask: | Glossy green |

| Silkscreen: | White |

| Special Process | Buried & Blind vias |

FAQs

PTFE is a synthetic thermoplastic fluoropolymer and is the second most commonly used PCB laminate material. It offers consistent dielectric properties at a higher coefficient expansion than standard FR4.

PTFE lubricant provides high electrical resistance. This enables it to be employed for use on electrical cables and circuit boards.

At RF and Microwave frequencies, the dielectric constant of standard FR-4 Material (approx. 4.5) is often too high, resulting in significant signal loss during transmission across the PCB. Fortunately, PTFE materials boast dielectric constant values as low as 3.5 or below, making them ideal for overcoming the high-speed limitations of FR-4.

The simple answer is that they are the same thing: Teflon™ is a brand name for PTFE (Polytetrafluoroethylene) and is a trademark brand name used by the Du Pont company and its subsidiary companies (Kinetic which first registered the trademark & Chemours which currently owns it).

PTFE materials boast dielectric constant values as low as 3.5 or below, making them ideal for overcoming the high-speed limitations of FR-4.

Generally speaking, high frequency can be defined as frequency above 1GHz. Currently, PTFE material is widely used in high frequency PCB manufacturing, it's also called Teflon, which frequency is normally above 5GHz. Besides, FR4 or PPO substrate can be used to the product frequency among 1GHz~10GHz. These three high frequency substrates have below differences:

Concerning the laminate cost of FR4, PPO and Teflon, FR4 is the cheapest one, while Teflon is the most expensive one. In terms of DK, DF, water absorption and frequency feature, Teflon is the best. When product applications require frequency above 10GHz, only can we choose Teflon PCB substrate to manufacture. The performance of Teflon is far better than other substrates, However, the Teflon substrate has the disadvantage of high cost and large heat-resisting property. To improve PTFE stiffness and heat-resisting property function, a large number of SiO2 or fiber glass as the filling material. On the other hand, due to molecule inertia of PTFE material, which it is not easy to combine with copper foil, thus, it needs to do the special surface treatment on the combination side. Concerning combination surface treatment, normally use chemical etching on PTFE surface or plasma etching to plus surface roughness or add one adhesive film between PTFE and copper foil, but these may influence dielectric performance.